Custom Sand Casting Services

At EVERGREEN, you can obtain a one-stop sand casting solution: from design to samples, small-batch trials, and mass production. Our engineers can solve any problem for you.

Capabilities

Weight of Components

1kg to 500 kg

Size of Components

All Size

Minimum Wall Thickness

6mm - 8 mm

Surface Finish (Ra) µ

Ra 50 µ

Dimensional Accuracy

CT10 - CT12

Why Choose EVERGREEN's Custom Sand Casting Services?

No matter what kind of product you need, or how many you need, EVERGREEN can guarantee that the products we provide are of high dimensional accuracy, the best quality, and the most affordable prices. Our team responds quickly and provides professional service to meet all your needs.

- The engineering team has extensive manufacturing experience and professional knowledge.

- Two engineers are assigned to a project to coordinate and proactive DFM.

- Complete and advanced in-house sand casting equipments

- Manufacturing high-quality, high-performance sand-cast components

- Extremely competitive pricing within the industry

- Industry-leading turnaround time

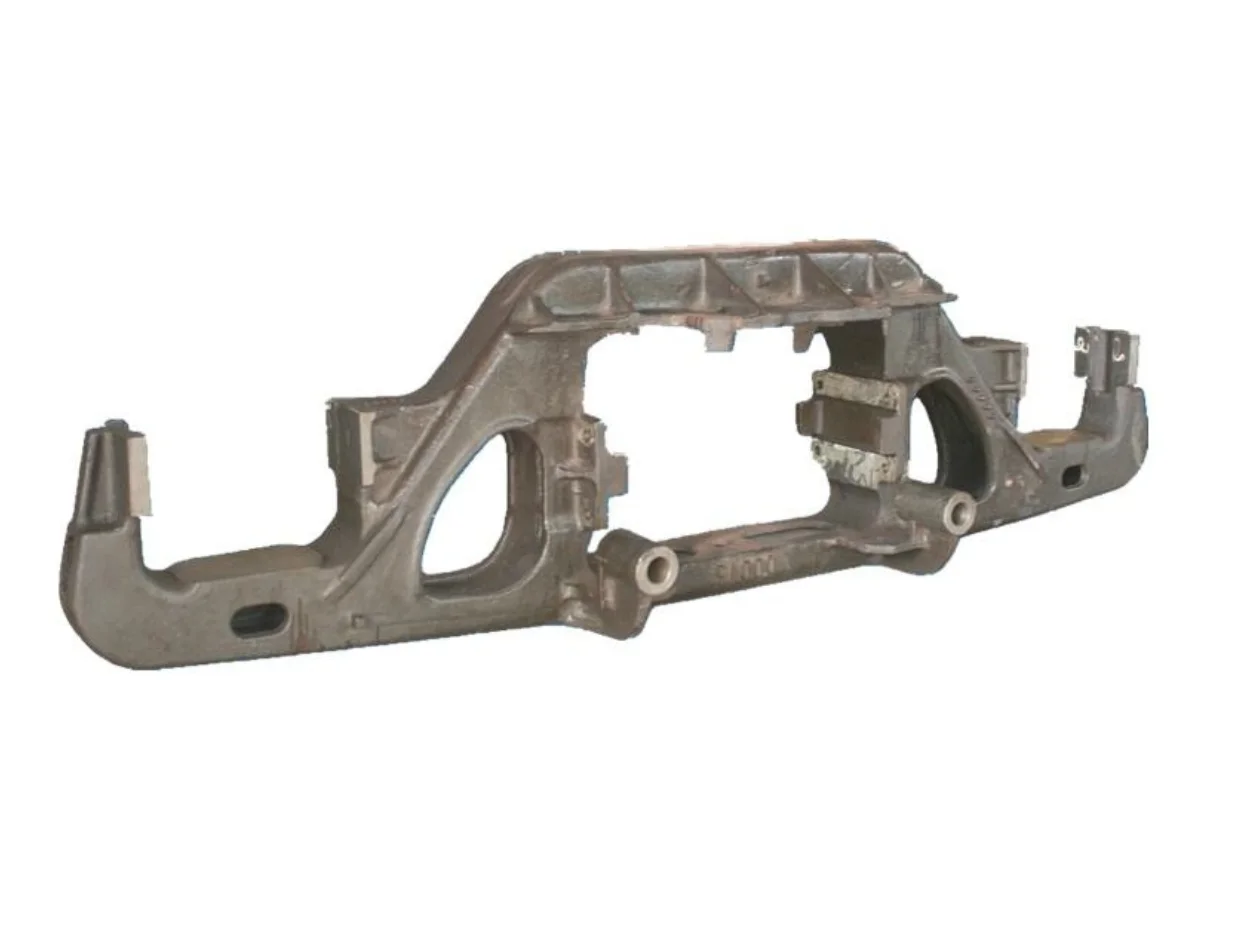

Case Applications of Sand Casting Parts

Pump Housing

Excavator Bucket Teeth

Differential Housing

Gearbox Housing

Bearing Housing

Bogie

Sand Casting Mold

EVERGREEN possesses extensive experience in the foundry industry, including mold design and manufacturing. We maintain stringent standards for dimensional accuracy and cost control in foundry molds, aiming to produce high-precision sand casting molds at minimal cost.

Prior to mold fabrication, casting simulation software is indispensable. Through multiple casting simulations, we identify potential problem areas and implement targeted adjustments. This ensures the production of high-quality sand-cast parts with low defect rates, ultimately reducing your costs.

Optional Surface Finishes

At EVERGREEN, we can also provide surface treatment for your sand cast parts, such as anodizing to improve corrosion resistance and wear resistance; electroplating to enhance surface hardness and aesthetics; powder coating, which is cost-effective yet weather-resistant and corrosion-resistant; as well as electrophoresis, sandblasting, and polishing.

Materials Suitable for Sand Casting

In EVERGREEN’s sand casting workshop, you can choose from a wide variety of materials for sand casting. We purchase sand casting raw materials that have undergone strict incoming inspections to ensure they are of the highest quality, so you can choose with confidence.

- Grey cast iron: Offers excellent castability, wear resistance, and machinability at a relatively low cost. It is well-suited for casting engine blocks, brake discs, pump housings, and transmission cases.

- Ductile iron: Combines the excellent properties of cast iron with strength and toughness approaching that of steel. This is achieved by adding nodularizing agents during smelting, which transforms the internal graphite into spherical nodules. It is suitable for manufacturing components such as camshafts, gears, connecting rods, and valve bodies.

- Carbon steel: High strength and good toughness, its properties can be adjusted through carbon content and heat treatment. Suitable for manufacturing gears in heavy machinery, railway vehicle couplers, bogies, and similar components.

- Alloy steel: By adding alloying elements such as chromium, nickel, and molybdenum to carbon steel, higher strength, hardness, wear resistance, and corrosion resistance can be achieved. It is suitable for manufacturing mining machinery components, petroleum drilling equipment, and turbine parts.

Is your product suitable for sand casting?

If you’re considering custom metal parts, sand casting may be the most practical and cost-effective casting process. However, not all components are suitable for sand casting. To determine if your product is a good fit for sand casting, read on.

What Products Are Suitable For Sand Casting?

- Large component dimensions: Due to the extremely low cost of sand casting molds, this process is highly suitable for larger components ranging from several kilograms to several tons. Examples include engine blocks, machine bases, or large valves.

- Small-to-medium batch production: Sand molds require re-molding after each pour. While production efficiency is lower than metal molds, the mold costs for sand casting are virtually negligible compared to the high mold expenses of other casting processes (such as die casting). This makes sand casting highly suitable for small-to-medium batch production.

- Casting Materials: Sand casting processes impose no restrictions on materials. Whether gray iron, ductile iron, carbon steel, stainless steel, bronze, or aluminum, sand casting can be employed for all.

- Low surface finish requirements: Sand castings typically have a relatively rough surface. If your part does not demand high surface quality, sand casting is a viable option.

Situations Where Sand Casting is Not Suitable

- For parts requiring high dimensional accuracy and surface finish, die casting or investment casting is recommended.

- Sand casting is not suitable for very small products or thin-walled products.

- Parts requiring high-volume production are not suitable for sand casting.

Why Use Sand Casting?

What is Sand Casting

Sand casting is an ancient casting method that has been in use for thousands of years. Bronze and iron artifacts from antiquity were produced using sand casting techniques. To this day, it remains one of the most widely used casting processes.

How Does Sand Casting Work?

To give you a deeper understanding of what sand casting is, I’ve decided to walk you through the sand casting process. This way, you can gain a very clear and intuitive grasp of sand casting.

- Mold making: First, our engineers will create a model based on your part drawings (used to replicate the product’s shape, consisting of upper and lower halves), typically made from wood or aluminum. If the product has a cavity, a sand core shaped to match the cavity will also be produced.

- Sand mold making: Place each mold into a separate sand box, then fill and compact the box with foundry sand, or cover the sand with a plastic mold and apply vacuum pressure. Next, remove the molds, insert the sand core, and join the two sand boxes together. This process leaves a perfect cavity within the tightly packed sand.

- Pouring the metal: Next, the pre-melted metal can be poured into the sand mold through the sprue. Under the force of gravity, the molten metal will fill all the voids.

- Cooling and Sand Removal: After the molten metal has cooled and solidified, break the sand mold to remove the formed metal part.

- Post-processing: Remove excess sand and excess metal from the gate, then proceed with grinding, sandblasting, or other surface treatments as required.

The sand casting process is now complete. The main challenges lie in model fabrication and sand mold preparation. Successfully executing these two steps ensures high-quality sand-cast parts with minimal defects.

What are the advantages of sand casting?

- Exceptional dimensional flexibility: This is one of sand casting’s core advantages. From small parts weighing just a few grams to massive components like large machine bases or structural elements for wind power equipment weighing hundreds of tons, sand casting can produce them all. This capability to handle extreme dimensions is unmatched by many other casting processes.

- Low mold costs: Sand casting molds are typically categorized as wooden or aluminum molds, with significantly lower costs and production cycles compared to steel molds used in other casting processes, such as die casting. This translates to minimal upfront investment for your project, making it highly suitable for small-batch production and rapid prototyping.

- Part Complexity: Sand casting can produce relatively complex parts, such as intricate internal cavities, deep recesses, and undercut structures, all of which can be easily achieved using custom sand cores.

- No material restrictions: Sand casting is not “picky” and can be used for casting nearly any alloy, such as gray iron, ductile iron, carbon steel, alloy steel, aluminum alloys, copper alloys, and magnesium alloys. You can freely select the most suitable material based on your requirements for the part’s mechanical properties, wear resistance, corrosion resistance, or cost, without being constrained by the casting process.

- Rapid prototyping iteration speed: When you complete a sample and find its dimensions are unsuitable, requiring design and mold modifications, you only need to adjust the wooden pattern. Compared to modifying hard molds, this saves significant time and cost. Therefore, sand casting is an ideal choice for new product development and prototype validation.

- Excellent material properties: Since sand casting relies on natural cooling, the slower cooling rate allows the molten metal to fully fill the mold cavity, reducing internal defects such as porosity and shrinkage cavities. It also promotes refinement of the metal grain structure and reduces internal stresses, resulting in castings with more stable and uniform mechanical properties. This is particularly crucial for large, thick-walled components.

Choose EVERGREEN's Custom Sand Casting Services

If you need a reliable, experienced partner to manufacture high-quality sand castings, you can confidently choose EVERGREEN Machinery. We offer flexible, one-stop sand casting solutions: from design to prototyping, small-batch trials, and full-scale production. Our engineers remain actively involved throughout, providing regular project progress updates.

With over 20 years of deep expertise in sand casting, we welcome your inquiries anytime. Contact us for a complimentary technical assessment and quotation!

Sand Casting FAQ

What information do I need to provide to get an accurate quote?

Of course, the more detailed information you provide, the more accurate and prompt our quotation will be. The following details are crucial:

1. Material Specifications: The exact alloy grade of your part material (e.g., HT250 gray iron, QT500 ductile iron).

2. Annual Demand: Your projected annual purchase volume or single-batch quantity, which impacts our mold planning and unit pricing.

3. Weight: This directly impacts the amount of material required per blank.

4. Post-processing: Whether you require additional services such as heat treatment, shot blasting, machining, or surface coating.

Can sand castings have internal defects such as porosity or sand holes?

We fully understand your concerns in this regard, as this is a key measure of a foundry’s technical capabilities. Of course, EVERGREEN excels in this area:

Process Design: During the mold design phase, we utilize casting simulation software to analyze molten metal flow and solidification processes. This allows us to predict potential defect zones in advance and implement corrective measures.

Process Control: Throughout casting production, we strictly control sand mold strength, moisture content, and molten metal pouring temperature.

Post-Production Inspection: Our quality engineers conduct comprehensive checks on finished products, including visual inspections, dimensional measurements, and non-destructive testing. This ensures you receive only the highest quality products, accompanied by an 8D report.

More knowledge

Merry Chrismas!

EVERGREEN Machinery wishes everyone a Merry Christmas and a happy day every day!

The Difference Between Roughing and Finishing in Machining

The core purpose of CNC machining is to remove excess material from a workpiece, producing a part that precisely matches the specifications on the blueprint.

CNC Machining: A Comprehensive Overview

Simply put, CNC machining = digital program instructions + computer control system + automated machine tools + closed-loop feedback execution

EVERGREEN Factory Move In New Site

August 9, 2025, is a memorable day as EVERGREEN Machinery marks a significant milestone in its development—the grand opening of its new factory!