Custom Die Casting Services

Customize die-cast parts in various materials and sizes. Lower costs, better quality, and a highly professional die-casting parts supplier.

Capabilities

Weight of Components

0.01kg to 20 kg

Size of Components

Small and medium(≤1.5m)

Minimum Wall Thickness

0.7mm(aluminum), 0.5mm (zinc)

Surface Finish (Ra) µ

Ra 0.8µ - Ra 6.3µ

Dimensional Accuracy

CT6 - CT9

Why Choose EVERGREEN's Custom Die Casting Services?

No matter what kind of product you need, or how many you need, EVERGREEN can guarantee that the products we provide are of high dimensional accuracy, the best quality, and the most affordable prices. Our team responds quickly and provides professional service to meet all your needs.

- The engineering team has extensive manufacturing experience and professional knowledge.

- Two engineers are assigned to a project to coordinate and proactive DFM.

- Complete and Advanced In-house Equipments

- Die casting capability for highly complex parts

- Extremely competitive pricing within the industry

- Industry-leading turnaround time

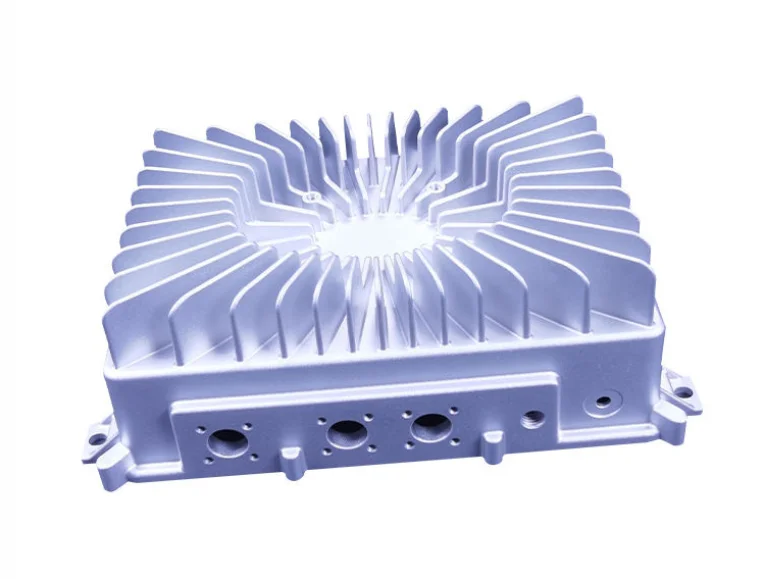

Case Applications of Die Casting Parts

High-Performance Medical Components

Die Cast Custom Automotive Parts

Die Cast Aerospace Components

Telecom Equipment Enclosure

Industrial Equipment Components

Energy Industry Enclosures

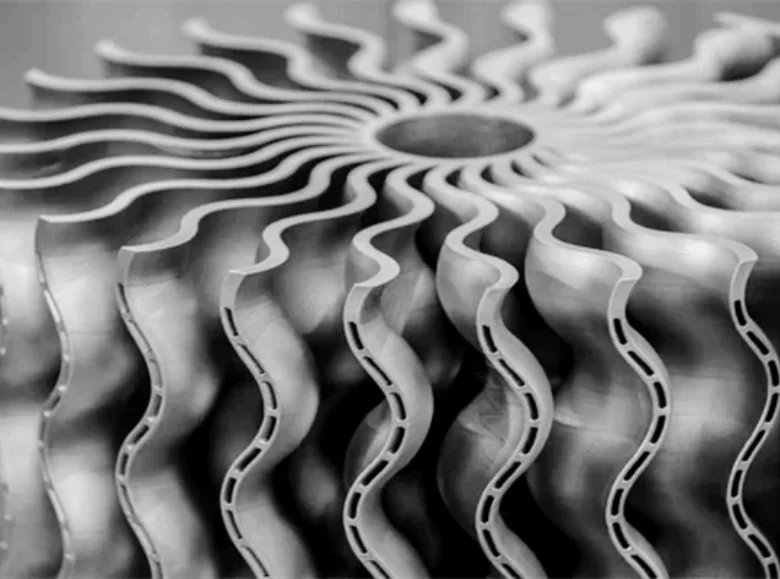

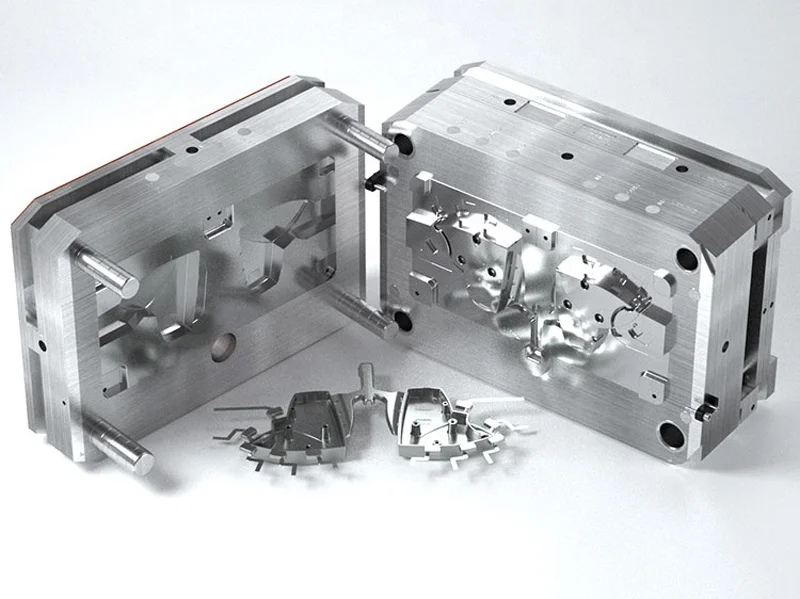

Die Casting Mold

Before manufacturing die-casting molds, we first simulate the die-casting process of the product several times using casting simulation software. Based on the simulation data, we optimize the mold design to eliminate fatal defects at the source, such as stagnant flow and jet flow that can cause surface defects and structural weakening.

We can also optimize and reinforce the cooling system and main stress points of the mold based on the data simulated by die casting, which can effectively extend the service life of the mold, improve production efficiency, and reduce the scrap rate.

Optional Surface Finishes

At EVERGREEN, we can also provide surface treatment for your die-cast parts, such as anodizing to improve corrosion resistance and wear resistance; electroplating to enhance surface hardness and aesthetics; powder coating, which is cost-effective yet weather-resistant and corrosion-resistant; as well as electrophoresis, sandblasting, and polishing.

Materials Suitable for Die Casting

In EVERGREEN’s die casting workshop, you can choose from a wide variety of materials for die casting. We purchase die casting raw materials that have undergone strict incoming inspections to ensure they are of the highest quality, so you can choose with confidence.

- Aluminum alloy: The core advantages of aluminum alloy lie in its light weight, high strength, and corrosion resistance. It is ideal for manufacturing automotive engine components, transmission housings, and battery enclosures for new energy vehicles. The most commonly used aluminum alloys include A380, A383, A413, and B390.

- Zinc alloy: The mechanical properties and strength of die-cast zinc alloy are unmatched by aluminum alloy. Zinc alloy has a strength close to that of low-carbon steel and excellent fluidity, making it suitable for die-casting thin-walled and complex parts.

- Magnesium alloy: Magnesium alloy is arguably the lightest metal among common metals. Its density is only two-thirds that of aluminum alloy, making it the ultimate choice for lightweight applications. Despite its light weight, it has high strength and rigidity, as well as excellent shock absorption properties.

A Quick Guide to Designing Die Casting Parts

Optimizing your design, avoiding unnecessary features, and limiting the complexity of die-cast parts can help you reduce die-casting costs and time, effectively improving the production efficiency of die-cast parts.

Optimize Inner Corner Radius

Design the largest possible radius (R angle) for all internal corners. This has three advantages:

1. The rounded corners facilitate the smooth flow of molten metal, reduce turbulence, and effectively prevent insufficient filling.

2. The rounded corners significantly reduce stress concentration in the casting during cooling and subsequent use, thereby extending the service life of the mold and preventing cracking.

Design Uniform Wall Thickness

The wall thickness of die-cast products should be designed to be as uniform as possible, avoiding areas that are too thick or too thin. If the wall thickness is uneven, different cooling rates will occur within the same part, leading to internal defects such as shrinkage cavities and porosity in the thicker areas. Uneven cooling and contraction can also cause warping and deformation of the part.Thin-walled areas (e.g., aluminum die-cast parts less than 0.8 mm and zinc die-cast parts less than 0.5 mm) may experience incomplete filling or insufficient strength.

Reasonable Design of Reinforcing Ribs

Add some reinforcing ribs to your die-cast parts in a reasonable manner to improve structural strength rather than increasing the overall wall thickness. Reinforcing ribs can significantly increase the rigidity and strength of die-cast parts with minimal material, while also avoiding defects caused by wall thickness. However, it is important to note that the thickness of the reinforcing ribs should not exceed 50%-60% of the wall thickness to which they are attached, and sufficient draft angles and radii should be designed for them.

Design Sufficient Draft Angles

Whether it is the inner surface or outer surface of a die-cast part, any surface perpendicular to the parting line must be designed with a draft angle. This is because the draft angle determines whether the die-cast part can be removed smoothly from the mold. If there is no draft angle or the angle is insufficient, it will result in difficulty in demolding and may even damage the mold. Generally, the angle for outer walls is typically 1°–2°, while inner walls require a larger angle of 2°–3° or more.

Simplify Complex Structures

When designing die-cast parts, it is important to avoid designing overly deep cavities, closed recesses, and narrow deep grooves. This is because complex structures often require additional mold components such as sliding blocks and inclined pins, which significantly increase mold complexity, manufacturing difficulty, and costs. Deep cavities and narrow grooves also pose challenges for venting and demolding.We recommend that you contact us during the design phase of your die-cast parts. Our engineers can collaborate with you to optimize the design and reduce the complexity of the mold structure.

Why Use Die Casting?

What is Die Casting

Die casting, also known as pressure casting, is a metal casting process that involves injecting molten metal into a die casting mold under high pressure. The die casting mold is equipped with cooling channels, allowing the molten metal to cool and solidify rapidly once it enters the mold. The mold is then opened, and the die-cast parts are ejected.The die casting process is highly automated, requiring minimal human intervention, making it ideal for producing large quantities of complex parts. However, die casting cannot be used to cast metals with melting points above 1000°C.

5 Advantages of Selecting Die Casting Process

High production efficiency: Die casting is renowned for its high degree of automation and high production efficiency. Once the mold is developed, the production cycle for a single die-cast part is extremely short, making it ideal for large-scale production with annual output ranging from tens of thousands to hundreds of thousands of units. Such high production efficiency and output result in very low costs per die-cast part. If you require large volumes of parts, die casting offers highly competitive costs.

- Complexity and precision: If your product has thin walls, complex internal structures, or pre-threaded holes, we recommend die casting. It can cast extremely complex parts with excellent dimensional tolerances and precision, and requires little or no secondary processing.

- High strength and durability: Die-cast components are manufactured by injecting high-quality aluminum, zinc, or magnesium alloys into molds under high pressure. This high-pressure forming process results in a highly dense molecular structure within the casting, granting it an exceptional strength-to-weight ratio and outstanding durability. Consequently, die-cast parts achieve lightweight construction while maintaining the ability to withstand heavy loads, impacts, and wear.

- Surface quality: Parts produced through die casting exhibit exceptionally smooth and refined surfaces, with some suitable for direct use as visible components. Moreover, die-cast parts perfectly replicate every detail of the mold surface, underscoring the critical importance of meticulous mold fabrication in the early stages. This is why die casting molds are more expensive than those for other casting processes. Die-cast parts are also highly suitable for various surface treatments, including electroplating, spray coating, and anodizing.

- Reducing waste: Die casting is a near-net-shape process, meaning die-cast parts require minimal post-machining and generate very little scrap. Additionally, while the mold’s gates and overflow system produce some waste during die casting, this material can be 100% recycled and reused.

Die Casting FAQs

Is the cost of die casting molds very high?Is the cost of die casting molds very high?

Yes, it can be said that die-casting molds are the most expensive among all casting process molds. This is determined by the characteristics of the die-casting process itself. Since die-casting molds must repeatedly withstand high-pressure impacts and high temperatures during operation, they require high-heat-resistant and high-strength mold steel. These molds are manufactured through complex processes such as precision CNC machining and electrical discharge machining (EDM).

Additionally, the mold requires internal cooling systems, ejection mechanisms, parting lines, gates, and venting systems. These design elements significantly increase manufacturing complexity, thereby driving up costs.

What is the typical production cycle for die casting?

The production cycle for die-cast parts is generally divided into two stages:

The first step is mold development. We begin by performing multiple simulations of the part using casting simulation software. Based on the simulated data, we then develop and manufacture the die-casting mold. This process typically takes 4-8 weeks (the duration also depends on the complexity of the mold and the part). This represents the project’s primary time investment.

Production follows immediately. Once the mold is debugged and ready, high-volume production proceeds at a rapid pace. The cycle time for a die-cast part ranges from tens of seconds to a few minutes.

How can I ensure my die-cast part design is both sound and cost-optimized?

To achieve the most rationally designed and cost-optimized die-cast parts, the best approach is to collaborate with EVERGREEN during the part design phase for manufacturability analysis. EVERGREEN’s engineers will review your 3D drawings in advance, providing expert recommendations on cost-influencing factors such as draft angles, wall thickness, fillet design, mold design, and ejection points. This prevents issues during mass production and reduces your project’s overall costs.

What is the achievable dimensional tolerance for die casting processes?

Die casting processes can maintain extremely tight dimensional tolerances, as die casting molds are manufactured through precision machining. For small-sized die castings, tolerances can be controlled within ±0.05mm to ±0.1mm.

More knowledge

Merry Chrismas!

EVERGREEN Machinery wishes everyone a Merry Christmas and a happy day every day!

The Difference Between Roughing and Finishing in Machining

The core purpose of CNC machining is to remove excess material from a workpiece, producing a part that precisely matches the specifications on the blueprint.

CNC Machining: A Comprehensive Overview

Simply put, CNC machining = digital program instructions + computer control system + automated machine tools + closed-loop feedback execution

EVERGREEN Factory Move In New Site

August 9, 2025, is a memorable day as EVERGREEN Machinery marks a significant milestone in its development—the grand opening of its new factory!