Custom Investment Casting Services

At EVERGREEN, you can obtain a one-stop investment casting solution: from design to samples, small-batch trials, and mass production. Our engineers can solve any problem for you.

Capabilities

Weight of Components

0.25kg to 50kg

Size of Components

Small and Medium

Minimum Wall Thickness

4mm - 5mm

Surface Finish (Ra) µ

Ra 25 µ

Dimensional Accuracy

CT7 - CT9

Why Choose EVERGREEN's Custom Investment Casting Services?

No matter what kind of product you need, or how many you need, EVERGREEN can guarantee that the products we provide are of high dimensional accuracy, the best quality, and the most affordable prices. Our team responds quickly and provides professional service to meet all your needs.

- The engineering team has extensive manufacturing experience and professional knowledge.

- Two engineers are assigned to a project to coordinate and proactive DFM.

- Complete and advanced in-house investment casting equipments

- Manufacturing high-quality, high-performance investment-cast components

- Extremely competitive pricing within the industry

- Industry-leading turnaround time

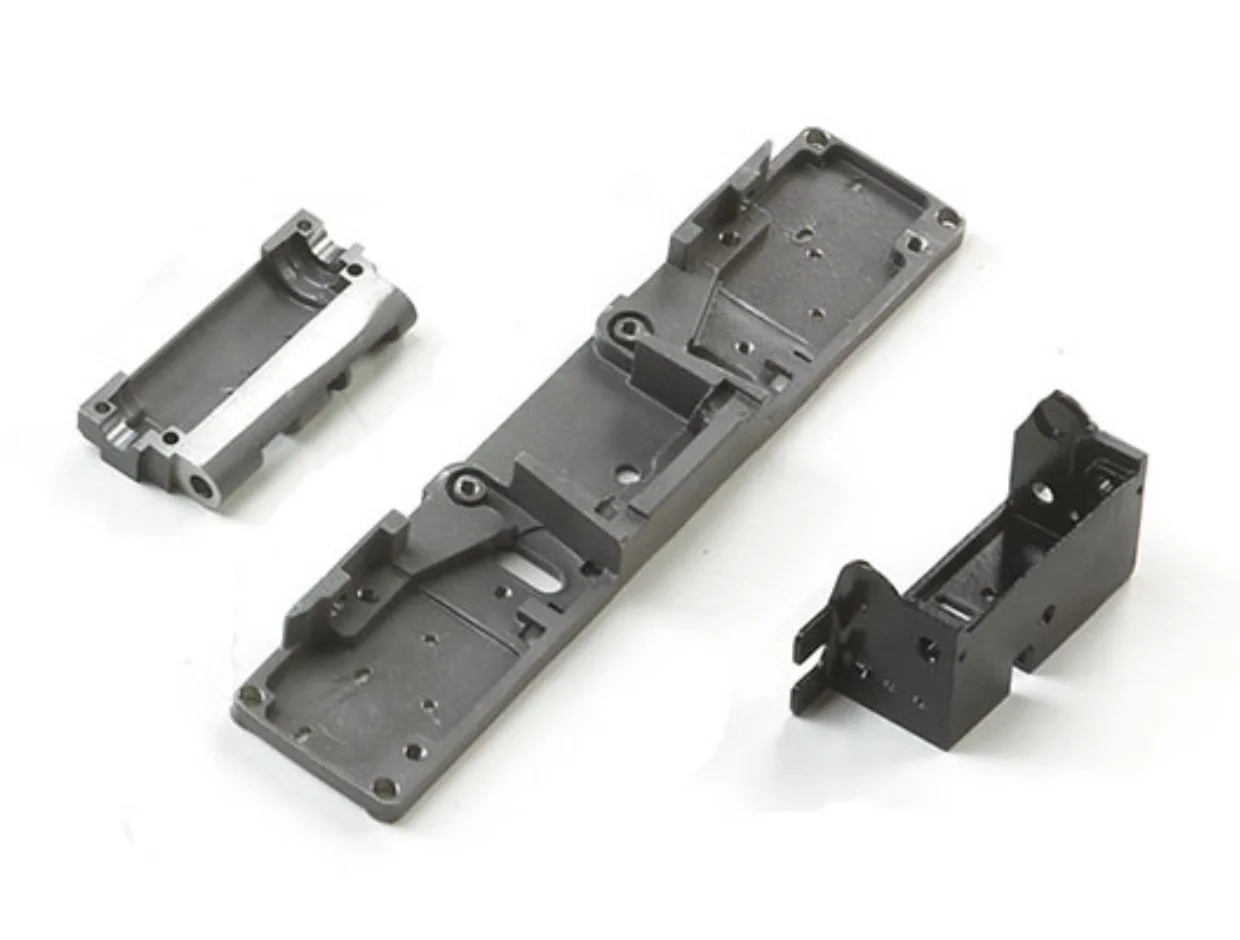

Case Applications of Investment Casting Parts

Impeller

Rocker Arm

Manifold

Sensor Components

Nozzle Ring

Lock Parts

Investment Casting Mold

Molds for investment casting can be categorized into two types: wax-pattern molds and metal-pattern molds. For wax-pattern molds, aluminum is typically used as the material. This choice is primarily due to aluminum's suitability for CNC machining, enabling the precise fabrication of intricate details. Additionally, aluminum's high thermal conductivity facilitates rapid cooling and solidification of the molten wax. Other advantages include aluminum's lightweight nature and cost-effectiveness.

The second mold involves coating the surface of the fabricated wax pattern with refractory material to form a mold shell. We primarily use silica sol as the binder for this process. Mold shells produced with silica sol exhibit high hardness, excellent high-temperature resistance, and minimal shrinkage. Furthermore, the cast components feature high dimensional accuracy and superior surface finish.

Optional Surface Finishes

At EVERGREEN, we can also provide surface treatment for your investment cast parts, such as anodizing to improve corrosion resistance and wear resistance; electroplating to enhance surface hardness and aesthetics; powder coating, which is cost-effective yet weather-resistant and corrosion-resistant; as well as electrophoresis, sandblasting, and polishing.

Materials Suitable for Investment Casting

In EVERGREEN’s investment casting workshop, you can choose from a wide variety of materials for investment casting. We purchase investment casting raw materials that have undergone strict incoming inspections to ensure they are of the highest quality, so you can choose with confidence.

- Carbon steel and alloy steel: These two materials are the most commonly used and economical, frequently employed in manufacturing automotive components, structural parts, and similar applications. Common grades include 1020, 1040, 4140, and 4340.

- Stainless steel: Possesses relatively outstanding hardness and excellent corrosion resistance, commonly used to manufacture ship components, food processing machinery, pump and valve housings, and chemical equipment. The most frequently used grades include 304, 316, 410, and 420.

- Aluminum and aluminum alloys: Aluminum materials offer a balanced combination of strength, lightweight properties, and corrosion resistance, making them highly suitable for lightweight aerospace structural components and automotive parts. Commonly used grades include A356 and A357.

Is your product suitable for investment casting?

If you’re considering customizing a batch of intricate metal components, investment casting may be within your options due to its exceptional precision. However, not all parts are suitable for this process. Failing to select the most appropriate method could increase costs and compromise product quality.

Is your part structure complex?

The exceptional reproduction of fine details and intricate internal cavities represent a core advantage of investment casting. If your casting requirements involve the following challenges, you should prioritize investment casting as your preferred method.

- Monolithic casting requirements: If your part consists of multiple components, would you prefer to integrate them into a single unit? Investment casting can effortlessly produce parts featuring intricate internal cavities, flow channels, or nested structures. This approach offers several advantages: it reduces assembly steps, minimizes the risk of loosening, and enhances overall structural integrity.

- Part Complexity: When your designed parts feature intricate thin walls, complex curved surfaces, irregular deep holes, or difficult-to-machine areas, investment casting proves the most suitable solution. It precisely replicates every detail, significantly reducing subsequent machining costs.

- Surface Requirements: If your parts require exceptionally smooth surfaces and you wish to minimize subsequent CNC machining steps such as grinding and polishing, investment casting is your optimal choice.

What is the material of your parts?

Have you selected stainless steel, tool steel, or high-temperature alloys for manufacturing your components? These materials are exceptionally hard, leading to rapid tool wear, low efficiency, and high costs during CNC milling. By opting for investment casting, you can significantly reduce the substantial expenses associated with subsequent machining processes.

Do you have a high demand?

If your product requirements range from tens of thousands to hundreds of thousands of units, this constitutes a relatively large batch size, making die casting a more suitable option. Investment casting, on the other hand, is better suited for small to medium batches of custom parts.

Why Use Investment Casting?

What is Investment Casting

Simply put, investment casting involves first creating a shape of our part using easily meltable material (the investment pattern). Multiple layers of refractory material are then repeatedly coated onto this pattern. After allowing it to dry, the pattern is heated and melted away, leaving behind a hollow mold cavity. Finally, molten metal is poured into this cavity.

How Does Investment Casting Work?

To give you a deeper understanding of what investment casting is, I’ve decided to walk you through the investment casting process. This way, you can gain a very clear and intuitive grasp of investment casting.

- Mold Design and Manufacturing: First, we design and machine a high-precision metal mold (typically an aluminum mold) based on the part’s 3D data. Its cavity directly determines the shape of the wax pattern, which ultimately dictates the form of the metal part.

- Wax Injection: The prepared wax-based material is heated to a semi-fluid state, then injected into an aluminum mold using a wax injection machine. This creates a wax model identical in shape to the final part. After removal, it is placed in water to cool, preventing deformation.

- Wax Pattern Assembly: Wax patterns removed from aluminum molds may exhibit imperfections or parting lines, requiring manual trimming. Multiple wax patterns are then assembled onto a shared wax pouring system (including the sprue cup, main sprue, feeder sprues, and internal sprues) using wax soldering, forming a complex “wax pattern tree.” This allows multiple parts to be cast simultaneously, enhancing production efficiency.

- Shell molding: This is a continuous cycle of slurry dipping, stuccoing, and drying. Slurry dipping involves immersing the wax pattern tree into a slurry composed of extremely fine refractory powder (zircon sand, corundum powder) and a binder (silica sol). Stuccoing entails sprinkling coarser refractory sand particles onto the slurry layer, allowing it to dry, and then repeating the process—typically requiring 5 to 9 layers.

- Dewaxing: Place the fully dried mold shell into the dewaxing kettle, where the wax pattern melts and flows out, leaving behind a cavity that perfectly matches the final part’s shape.

- Firing: Place the dewaxed molds into a high-temperature baking furnace (800°C – 1100°C) to remove residual wax, moisture, and volatile substances. This process also enhances the molds’ high-temperature strength and stability. Most importantly, it preheats the molds to a very high temperature, ensuring the molten metal does not solidify prematurely during pouring due to excessive temperature differences.

- Pouring: Next, pour the molten metal into the mold. After cooling, shake off the mold shell to obtain the part.

This concludes the entire investment casting process, which is indeed a relatively complex casting technique. However, we have accumulated over a decade of experience in this field, so you can confidently entrust your project to us.

What are the advantages of investment casting?

- High dimensional accuracy: Parts produced via investment casting exhibit precise dimensions and tight tolerances, closely approximating the final part geometry. This allows for reduced or even eliminated allowances during wax pattern design. Such precision not only reduces casting weight and costs but also minimizes subsequent machining time, further lowering expenses. Certain non-critical surfaces may even be utilized directly.

- Part Complexity: This is arguably the core advantage of investment casting. It enables the production of thin-walled components, intricate internal cavities, and minute holes—shapes unattainable through other casting methods or even machining. Products that previously required multiple assembled parts can now be integrated into a single casting using investment casting. This not only enhances part stability but also reduces overall costs.

- The range of castable materials is extensive: investment casting can produce nearly all alloy materials, such as carbon steel, alloy steel, stainless steel, and aluminum alloys. However, its greatest advantage lies in casting high-hardness, difficult-to-machine, and high-value materials. This is because it can directly cast parts close to their final shape, avoiding the cost waste associated with subsequent machining.

Choose EVERGREEN's Custom Investment Casting Services

If you need a reliable, experienced partner to manufacture high-quality investment castings, you can confidently choose EVERGREEN Machinery. We offer flexible, one-stop investment casting solutions: from design to prototyping, small-batch trials, and full-scale production. Our engineers remain actively involved throughout, providing regular project progress updates.

With over 20 years of deep expertise in investment casting, we welcome your inquiries anytime. Contact us for a complimentary technical assessment and quotation!

Investment Casting FAQ

How long does the entire production process take? What is the lead time?

Investment casting is a multi-step, relatively complex precision casting process with a longer production cycle. From finalizing the 3D drawings to delivering the first batch of samples typically takes 4 to 8 weeks. The majority of this time is spent on wax pattern design and development (2-3 weeks) and the mold shell fabrication process. Once mass production begins, our efficiency improves and lead times are correspondingly reduced.

We are overseas customers. Will communication and sample confirmation be troublesome?

You needn’t worry about communication issues at all. With our extensive experience in international collaboration, working with us will be a seamless process. Our professional technical sales representatives and project engineers are fluent in English and can efficiently handle technical and commercial communications with you via email, video conferences, and other channels—eliminating any time zone or language barriers. We will also provide regular project progress updates, complete with high-definition photos and videos.

After the castings are completed, what post-processing and machining services do you provide?

We provide a one-stop solution from design to prototyping, small-batch trials, and mass production. You no longer need to source multiple suppliers for subsequent processing. Our standard post-processing for castings includes trimming gates, shot blasting, and other cleaning procedures, delivering standard rough castings. Of course, we can also provide heat treatment, machining (precision turning, precision milling), and surface treatments (powder coating, phosphating, passivation, etc.).

More knowledge

Merry Chrismas!

EVERGREEN Machinery wishes everyone a Merry Christmas and a happy day every day!

The Difference Between Roughing and Finishing in Machining

The core purpose of CNC machining is to remove excess material from a workpiece, producing a part that precisely matches the specifications on the blueprint.

CNC Machining: A Comprehensive Overview

Simply put, CNC machining = digital program instructions + computer control system + automated machine tools + closed-loop feedback execution

EVERGREEN Factory Move In New Site

August 9, 2025, is a memorable day as EVERGREEN Machinery marks a significant milestone in its development—the grand opening of its new factory!