Custom Centrifugal Casting Services

At EVERGREEN, you can obtain a one-stop centrifugal casting solution: from design to samples, small-batch trials, and mass production. Our engineers can solve any problem for you.

Capabilities

Weight of Components

5kg to 500 kg

Size of Components

Medium and Large

Minimum Wall Thickness

3mm - 5mm

Surface Finish (Ra) µ

Ra 12.5µ - Ra 25µ

Dimensional Accuracy

CT8 - CT10

Why Choose EVERGREEN's Custom Centrifugal Casting Services?

No matter what kind of product you need, or how many you need, EVERGREEN can guarantee that the products we provide are of high dimensional accuracy, the best quality, and the most affordable prices. Our team responds quickly and provides professional service to meet all your needs.

- The engineering team has extensive manufacturing experience and professional knowledge.

- Two engineers are assigned to a project to coordinate and proactive DFM.

- Complete and advanced in-house centrifugal casting equipments

- Manufacturing high-quality, high-performance centrifugal-cast components

- Extremely competitive pricing within the industry

- Industry-leading turnaround time

Case Applications of Centrifugal Casting Parts

Vertical Centrifuge Components

Valve seat ring

Propeller Hub

Centrifugal Cast Gear Blanks

Bushings for Mining Industry

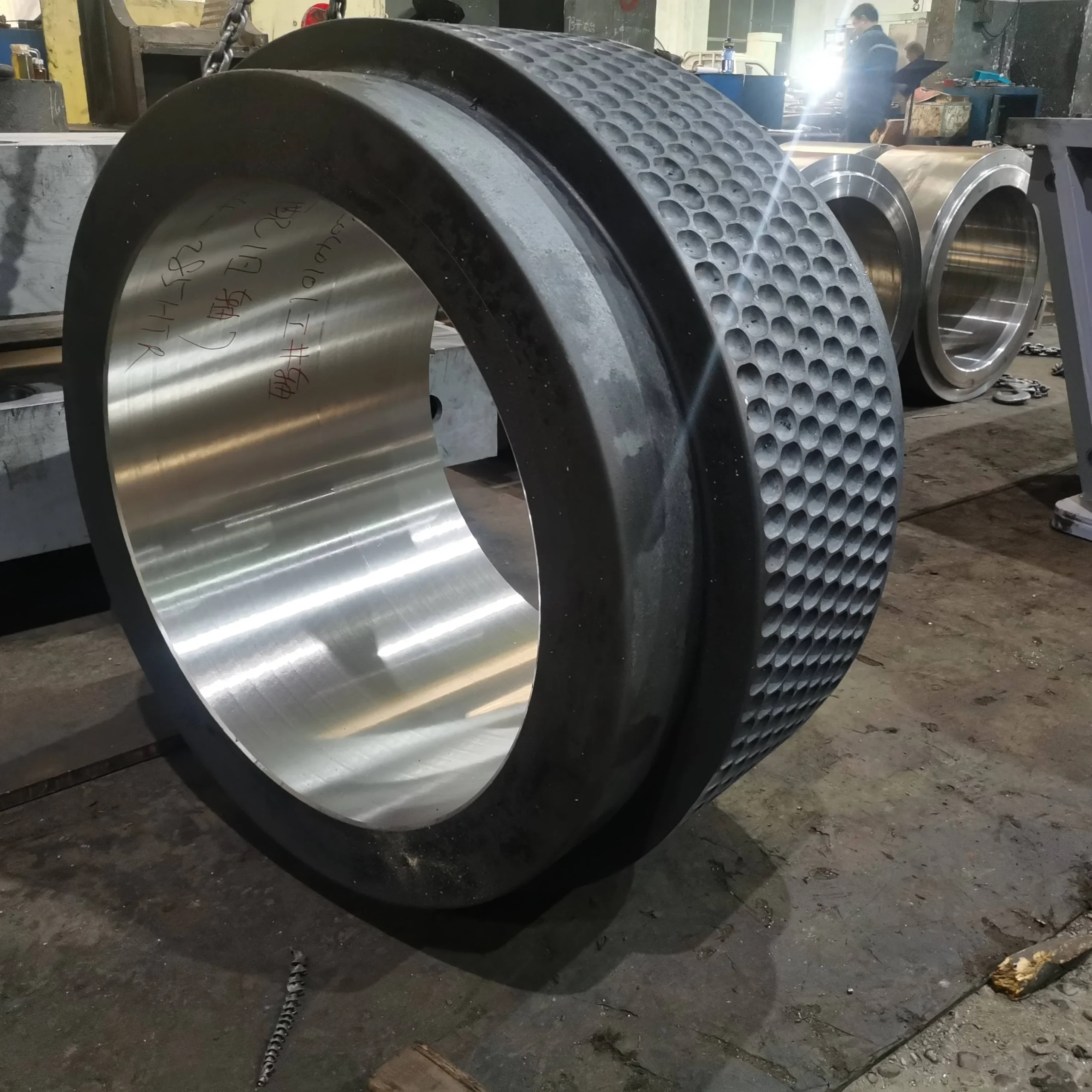

Briquetting Rolls

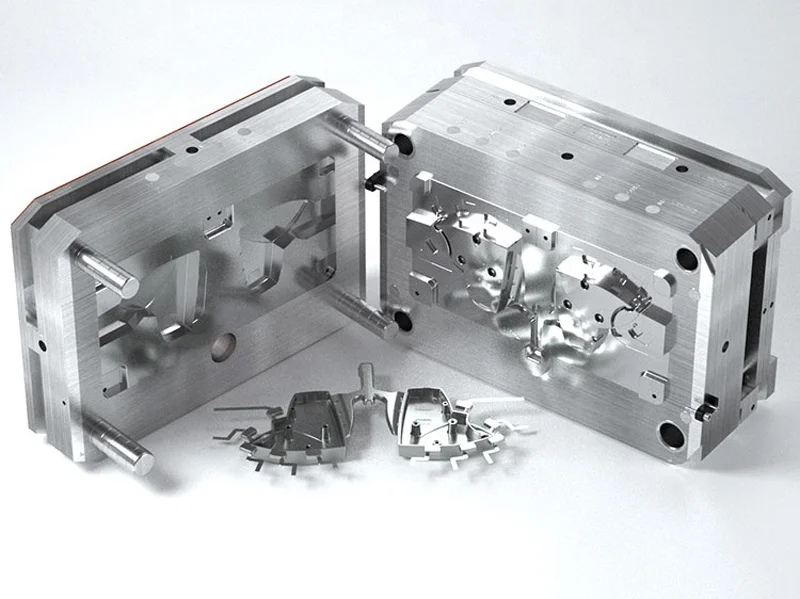

Centrifugal Casting Mold

Centrifugal casting molds offer multiple material options. The first type is metal molds, characterized by rapid heat transfer, high strength, and reusability. Typically made from heat-resistant steel or alloy steel, they are suitable for mass-producing cast steel and cast iron pipe fittings and sleeves. The second type is graphite molds, known for high-temperature resistance and ease of demolding. They are ideal for metals with high melting points but have a shorter lifespan compared to metal molds. The third type is low-cost, flexible sand/ceramic molds, suitable for small-batch or oversized parts, but they are disposable.

Optional Surface Finishes

At EVERGREEN, we can also provide surface treatment for your centrifugal cast parts, such as anodizing to improve corrosion resistance and wear resistance; electroplating to enhance surface hardness and aesthetics; powder coating, which is cost-effective yet weather-resistant and corrosion-resistant; as well as electrophoresis, sandblasting, and polishing.

Materials Suitable for Centrifugal Casting

In EVERGREEN’s centrifugal casting workshop, you can choose from a wide variety of materials for centrifugal casting. We purchase centrifugal casting raw materials that have undergone strict incoming inspections to ensure they are of the highest quality, so you can choose with confidence.

- Grey cast iron: This is a relatively ordinary material. If you don’t have high demands for strength and toughness, you can choose it for manufacturing rollers or sewer pipes.

- Ductile iron: Compared to gray iron, ductile iron offers significantly higher strength, toughness, and wear resistance. It is suitable for manufacturing engine cylinder liners, gear blanks, and other components.

- Carbon steel: such as AISI 1020, 1045, etc.

- Low-alloy steels: such as 4140, 4340, etc., can be heat-treated to enhance strength with minimal deformation. They are suitable for manufacturing gear blanks and bushings for heavy machinery.

- Stainless steel: Austenitic grades such as 304 and 316/316L are widely used in the chemical, food processing, and pharmaceutical industries for manufacturing pipelines, tanks, and components. Higher-strength grades like 2205 and 2507 are also available.

- Heat-resistant steels: such as P91, P92, etc., can operate continuously under high-temperature and high-pressure conditions.

- Copper alloys: Brass is suitable for manufacturing valves and pipe fittings, while bronze is suitable for manufacturing bushings, bearings, and gears.

Is Your Product Suitable for Centrifugal Casting?

If you’re searching for a reliable casting process to manufacture your parts, centrifugal casting may come to mind. But what exactly is this process? Is it suitable for producing your products? As a manufacturer with extensive experience in centrifugal casting, EVERGREEN can help you quickly find answers by addressing these key questions.

Does Your Product Meet These Criteria?

- Is the product shape cylindrical or annular?

This is the core advantage of centrifugal casting. Whether it’s simple pipes or structurally complex multi-layer sleeves, as long as they are symmetrical revolving bodies, it’s no problem.

- Do your parts have any requirements for density and strength?

Will your product be used in environments with high pressure, high temperature, high wear, and severe impact? If so, centrifugal casting is a suitable choice, as it produces parts with exceptionally dense internal structures.

- Are the materials used expensive?

Since centrifugal casting eliminates the need for gates and risers, it significantly improves material utilization. When working with expensive metals like stainless steel, high-chromium cast iron, and nickel-based alloys, this process can yield substantial cost savings.

If the answers to the above three questions are “Yes,” then centrifugal casting is likely your ideal choice.

Why Use Centrifugal Casting?

What is Centrifugal Casting

Centrifugal casting is a specialized casting method that utilizes centrifugal force generated by rotation. Molten metal is poured into a rapidly spinning mold, where it cools and solidifies to form a relatively dense casting.

Imagine spinning a bucket of water rapidly on the ground. Due to centrifugal force, the water clings tightly to the bucket’s walls. If the centrifugal force exceeds gravity, you can even turn the bucket upside down without spilling a drop. Centrifugal casting applies this principle on an industrial scale—only the water is replaced with molten metal, and the bucket becomes a mold.

How Does Centrifugal Casting Work?

To give you a deeper understanding of what centrifugal casting is, I’ve decided to walk you through the centrifugal casting process. This way, you can gain a very clear and intuitive grasp of centrifugal casting.

Below, we will use a common horizontal centrifugal casting pipeline production process as an example to break down its complete steps and understand the function behind each one.

- Prepare the mold: First, we must prepare the mold for casting. This mold is typically a metal mold, which is installed onto the centrifugal casting machine and thoroughly cleaned to prevent surface defects in the parts caused by residual metal shavings. At the same time, inspect the mold for cracks or deformation to prevent potential safety hazards.

- Spray Coating: After cleaning the mold, we apply a layer of special refractory coating to its inner walls. This coating prevents direct contact between the molten metal and the mold, extending the mold’s service life. It also reduces adhesion between the molten metal and the mold, improving the surface finish of the castings. Additionally, it functions as a release agent, ensuring the solidified castings can be easily removed from the mold.

- Preheat the mold: This step prevents excessive thermal stress and cracking during casting caused by significant temperature differences between the molten metal and the mold. Additionally, it evaporates moisture within the mold, preventing steam formation during casting that could lead to porosity in the casting.

- Startup and Pouring: Next, start the centrifuge. Once the mold reaches a certain rotational speed, steadily and continuously pour the precisely measured molten metal through the pouring channel into the mold. Pay attention to several key points during this step: 1. Always wait until the mold’s rotation is stable before beginning the pour; otherwise, turbulent flow will occur in the molten metal. 2. The volume of molten metal poured directly determines the pipe wall thickness and must be precisely calculated. 3. Maintain a steady and continuous flow during pouring to prevent defects such as interrupted flow or cold shuts.

- Solidification and Cooling: After pouring, the mold must remain in a state of high-speed rotation until the metal reaches a temperature safe for demolding. During this period, auxiliary cooling methods such as air blowing can be applied to the mold. During solidification, the metal solidifies gradually from the outer surface near the mold toward the interior. While the exterior solidifies, the interior remains liquid. The powerful centrifugal force continuously pushes the liquid metal inward toward the solidifying outer region. This process compensates for the volume shrinkage that occurs during solidification, fundamentally eliminating shrinkage cavities and porosity defects.

- Stop the machine and remove the casting: Once it is confirmed that the casting has cooled sufficiently to allow demolding, stop the centrifuge and remove the casting from the mold. During this step, pay attention to two critical details: 1. Ensure the casting has fully solidified. Otherwise, the unset molten metal, deprived of centrifugal force, may collapse or even spray out of the mold, posing extreme danger. 2. Remove the casting while it is fully solidified but still retaining significant residual heat. This leverages its thermoplastic properties to minimize demolding resistance.

The above outlines all the steps involved in centrifugal casting. While conventional casting processes typically rely on gravity, centrifugal casting represents a specialized method. It offers numerous advantages that other casting techniques cannot match.

What are the advantages of centrifugal casting?

- High material utilization: 1. Centrifugal casting eliminates the need for gates and runners found in sand casting and investment casting, significantly reducing raw material consumption. 2. During casting, we precisely calculate the exact material requirements for each part, resulting in minimal waste.

- Excellent casting quality: Centrifugal casting applies powerful centrifugal forces, resulting in parts with dense microstructures and smooth surfaces. This process eliminates defects such as porosity and slag inclusions.

- Uniform wall thickness: During casting, molten metal is evenly distributed across the inner walls by the high-speed rotation of the mold, resulting in castings with exceptionally uniform wall thickness.

- Suitable for a wide range of materials: Centrifugal casting can be applied to nearly all metallic materials, such as gray cast iron, ductile iron, aluminum alloys, copper alloys, stainless steel, alloy steel, and more. However, metals with good fluidity are more suitable.

Choose EVERGREEN's Custom Centrifugal Casting Services

If you need a reliable, experienced partner to manufacture high-quality centrifugal castings, you can confidently choose EVERGREEN Machinery. We offer flexible, one-stop centrifugal casting solutions: from design to prototyping, small-batch trials, and full-scale production. Our engineers remain actively involved throughout, providing regular project progress updates.

With over 20 years of deep expertise in sand casting, we welcome your inquiries anytime. Contact us for a complimentary technical assessment and quotation!

Centrifugal Casting FAQ

How can we ensure the quality of centrifugal castings? I'm concerned about potential quality issues.

You needn’t worry about the quality of centrifugal casting parts. In fact, producing high-quality components is the core strength of centrifugal casting. If you’re concerned about potential quality issues with centrifugal castings, take a look at how we ensure quality.

Physical Principle: During casting, powerful centrifugal force automatically pushes less dense slag and gases toward the inner surface of the casting. These minor imperfections are completely removed during subsequent boring operations. The final part you receive features an extremely dense internal structure.

Directional solidification: As the casting solidifies gradually from the outside in, the molten metal that has not yet solidified internally continuously exerts outward pressure under centrifugal force. This perfectly compensates for external metal shrinkage, fundamentally preventing issues such as shrinkage cavities and porosity.

Full-Process Quality Control: We prioritize product quality above all else. From raw material testing and process parameter control (temperature, rotational speed) to final non-destructive testing (UT/RT), we have established a comprehensive quality traceability system. Every finished product is of the highest standard.

More knowledge

Merry Chrismas!

EVERGREEN Machinery wishes everyone a Merry Christmas and a happy day every day!

The Difference Between Roughing and Finishing in Machining

The core purpose of CNC machining is to remove excess material from a workpiece, producing a part that precisely matches the specifications on the blueprint.

CNC Machining: A Comprehensive Overview

Simply put, CNC machining = digital program instructions + computer control system + automated machine tools + closed-loop feedback execution

EVERGREEN Factory Move In New Site

August 9, 2025, is a memorable day as EVERGREEN Machinery marks a significant milestone in its development—the grand opening of its new factory!