Precision Machining Services

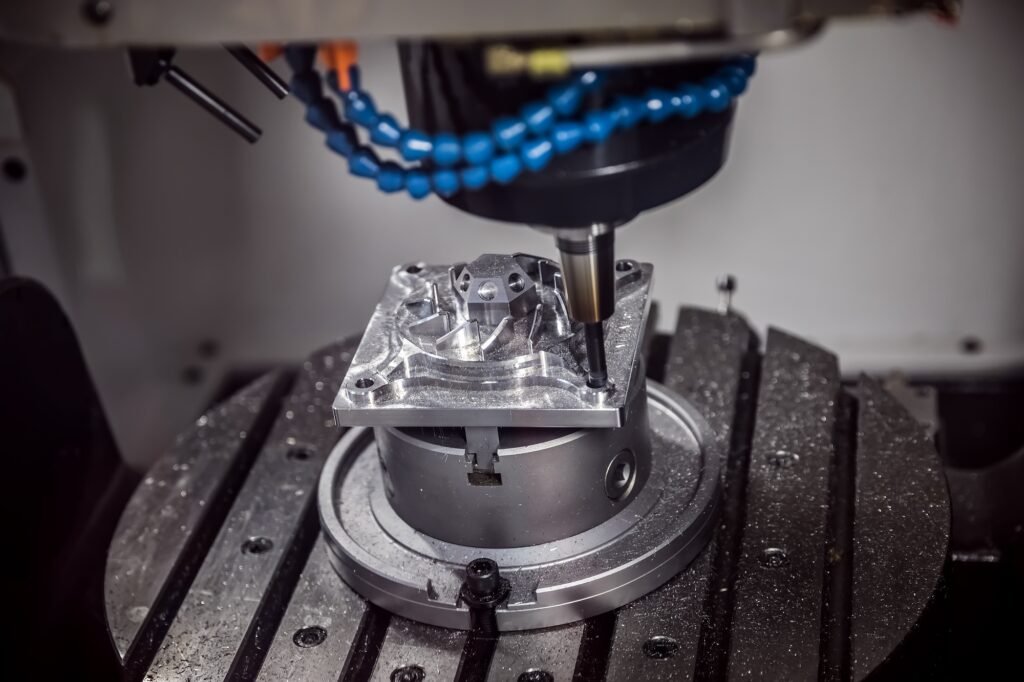

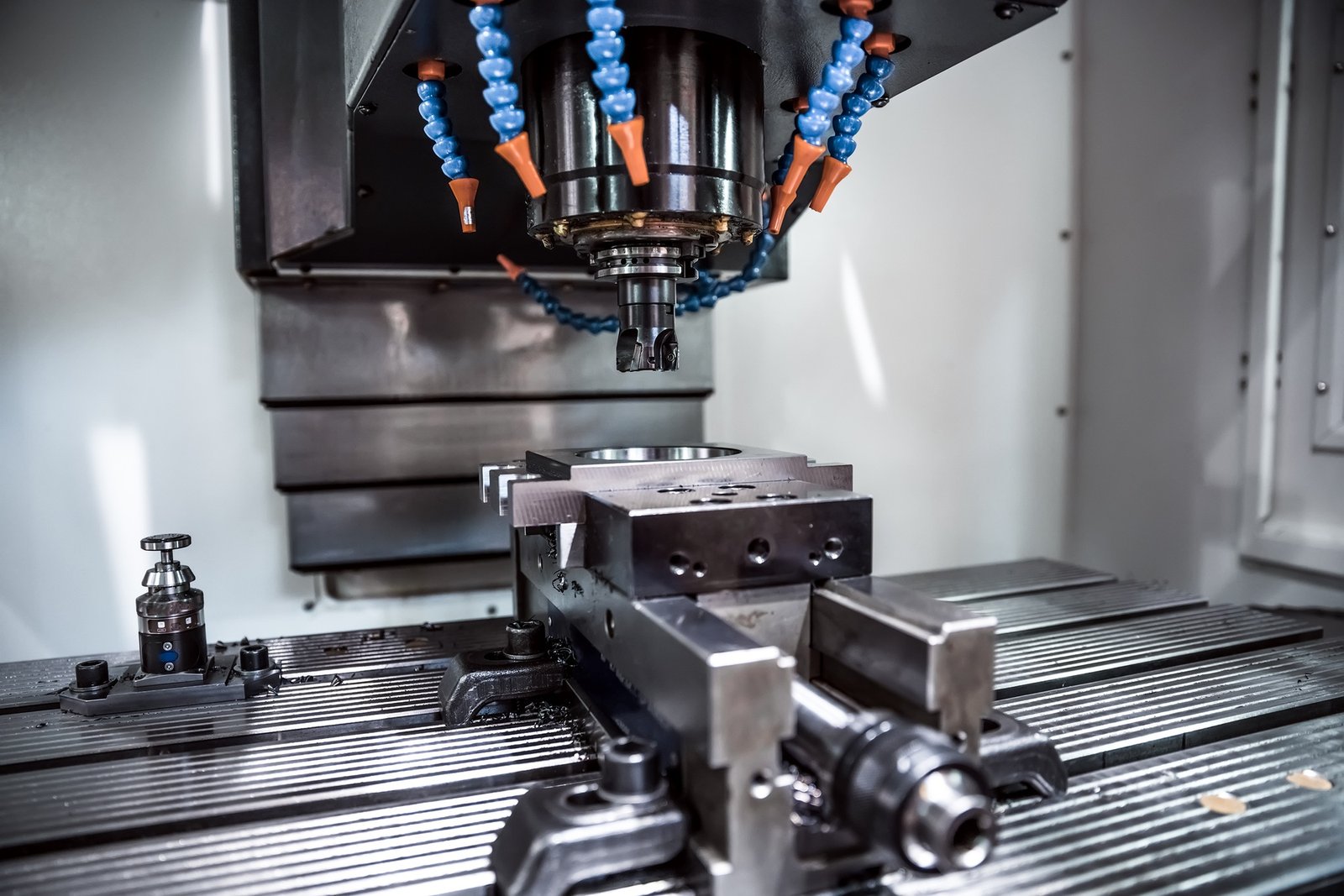

At EVERGREEN’s machining workshop, we are equipped with state-of-the-art precision machining equipment, including 5-axis machining centers, turning and milling machines, gantry machining centers, and more. We can provide you with one-stop precision machining solutions.

Whether it’s stainless steel or aluminum alloy, whether it’s precision prototype verification or large-scale production, EVERGREEN can deliver.

We specialize in manufacturing complex, non-standard precision parts, striving to provide you with high-precision, high-quality components. We continuously invest in new CNC machine tools and train highly skilled employees to ensure our team has a strong competitive advantage. To improve processing efficiency and quality, we are also constantly improving some material processing techniques to continuously meet our customers’ various production needs.

- Tolerance ±0.005 mm

- Experienced Engineer

- The Optimal Solution

- Rapid Prototyping

- Strict Quality Assurance

- Stable Delivery Date

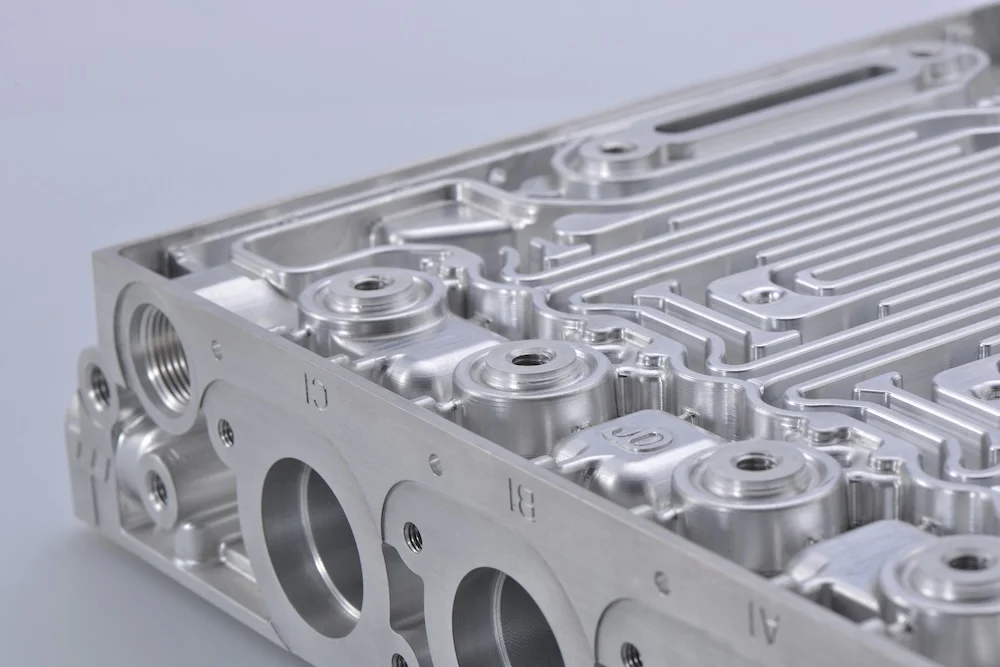

Custom Parts Manufacturing

If you require customized precision machining services, EVERGREEN is the ideal partner for you. With our professional expertise, extensive experience, and advanced skills, we are committed to becoming your most competitive supplier, particularly in terms of professionalism and cost-effectiveness. We strictly adhere to the ISO 9001 quality management system standards, combined with efficient production processes and flexible customization services, enabling us to deliver complex projects on time and provide products of the highest quality.

We can also provide some common surface treatments for your parts, such as sandblasting, shot blasting, polishing, electrophoresis, powder coating, and spray painting.

Prototype CNC Machining

Before manufacturing your customized parts, CNC prototyping is an effective method for validating complex designs and conducting pre-production testing. It helps us identify and resolve issues in a timely manner, ensuring that parts can smoothly transition into mass production.

In the early stages of the project, we will implement precise and cost-effective manufacturing processes to produce high-quality prototype parts for you. Our team of engineers will review and verify every project, analyze your design, and meet any special requirements, such as combinations with welding, EDM, or wire cutting processes. This is the only way to ensure you receive the optimal manufacturing solution.

Materials Suitable for Processing

Aluminum Alloy

Aluminum alloys are lightweight but have strength comparable to steel, making them ideal for use in the automotive and aerospace industries to achieve weight reduction. They also have excellent machinability.

Stainless Steel

The corrosion resistance, high hardness, and high wear resistance of stainless steel make it ideal for applications in industries such as medical devices, marine equipment, and precision bearings, including surgical forceps and chemical valves.

Titanium Alloy

Titanium alloys have exceptional hardness and extremely low weight, and are also resistant to high temperatures and corrosion, making them the material of choice for the aerospace and deep-sea industries.

Copper

Copper has extremely high processing efficiency and a surface finish of Ra0.8μm, making it ideal for small gears. At the same time, copper also offers excellent electrical conductivity and wear resistance.

4 Steps to Improve CNC Part Dimensional Stability

Eliminate material stress

Common methods for eliminating material stress are natural aging or vibration treatment. EVERGREEN first performs rough machining on the parts, then leaves them to age naturally for 2-3 hours before performing precision machining.

Improve the workpiece clamping method

Traditional three-jaw chucks can cause part deformation if the clamping force is uneven. In such cases, we typically switch to hydraulic expansion fixtures or vacuum suction platforms. For irregularly shaped parts, we also develop custom-designed soft jaws.

Improve cutting tool performance

The material and geometric parameters of cutting tools have a significant impact on machining accuracy. Selecting the wrong tool can also cause cutting vibrations, which have an even greater impact on accuracy. Therefore, selecting the correct tool is a critical step in the process.

Choose a reasonable machining process

EVERGREEN’s processing workflow generally consists of rough machining, semi-finishing, corner cleaning, cooling, and finishing. Cooling is an important step, as failure to cool can easily lead to heat accumulation and dimensional instability. For parts with high precision requirements, the number of semi-finishing steps needs to be increased.

EVERGREEN's Machining Factory

5-axis Machining Center

EVERGREEN can provide you with advanced 5-axis CNC machining systems, significantly enhancing the possibilities for processing parts made from various materials, shapes, and sizes, or even complex parts consisting of multiple components within a single assembly. We are capable of producing high-precision, complex parts to meet your exact requirements.

- High Processing Efficiency

- Higher Accuracy

- Outstanding Surface Finish

- Reduce Fixture Costs

- Short Processing Time

- Various Processing Techniques

Applications

The primary functions of rail vehicles are high speed, safety, and comfort. Therefore, the internal components of rail vehicles cannot function without the support of precision machining. For example, the gearboxes and suspensions inside the bogies of high-speed trains directly affect wheel alignment, requiring large-scale precision five-axis machining centers to ensure accuracy. Additionally, the machining accuracy of rail wheels directly impacts the smooth operation of trains.

In the construction machinery industry, some machinery and equipment face extremely harsh working conditions every day, including high impact and high vibration. This not only requires the materials used to manufacture parts to be of high quality, but also places extremely high demands on the precision of internal core components. For example, in hydraulic systems, even slight dimensional deviations in certain parts can lead to internal leakage, affecting high-pressure sealing and energy conversion. As a result, many internal core components require precision machining, grinding, boring, and EDM.

In the medical equipment industry, precision parts are indispensable. Some imaging equipment, such as CT and MRI rotating frames, slip rings, and precision bearings, require extremely high processing accuracy to ensure clear imaging without artifacts. We not only manufacture precision-machined equipment for the medical industry, but also produce sheet metal products, such as equipment cabinets.

Submit a Quick Quote

More knowledge

Merry Chrismas!

EVERGREEN Machinery wishes everyone a Merry Christmas and a happy day every day!

The Difference Between Roughing and Finishing in Machining

The core purpose of CNC machining is to remove excess material from a workpiece, producing a part that precisely matches…

CNC Machining: A Comprehensive Overview

Simply put, CNC machining = digital program instructions + computer control system + automated machine tools + closed-loop feedback execution

EVERGREEN Factory Move In New Site

August 9, 2025, is a memorable day as EVERGREEN Machinery marks a significant milestone in its development—the grand opening of…